ROVEX FIBER-REINFORCED POLYMER

THE MATERIAL SCIENCE BEHIND INNERGY AP

- Advanced composite material technology sets a new standard for performance applications

- Redefines structural strength with thermal performance

- Combines metal-like stiffness of aluminum and energy efficiency of polyamide for unprecedented fenestration applications

NEXT GENERATION FRP

CROSS-LINKING MAKES IT STRONG AND TOUGH.

ROVEX advances fiber-reinforced polymer (FRP) technology by cross-linking continuous strands of glass fiber with polyurethane polymer resin in a heat-accelerated continuous chemical reaction process called pultrusion.

Pultrusion: Deceuninck Rovex technology utilizes a specialized pultrusion process for providing high-strength products designed for manufacturing door and window parts. These PUR products offer many excellent performance features compared to other pultrusion technologies like those based on vinyl esters or polyester types.

The Rovex process pulls chemically-modified glass fibers through an injection box during which the glass fibers are impregnated by polyurethane (PUR) reactants. These PUR components, often referred to as the “iso” and “polyol,” covalently react forming urethane linkages connecting chains. In addition to the in-situ polymerization process, the modified glass fiber surface participates in covalent bonding interactions. The final product is comprised of 80% glass fibers that connect to a matrix of polyurethane linkages.

ROVEX DELIVERS

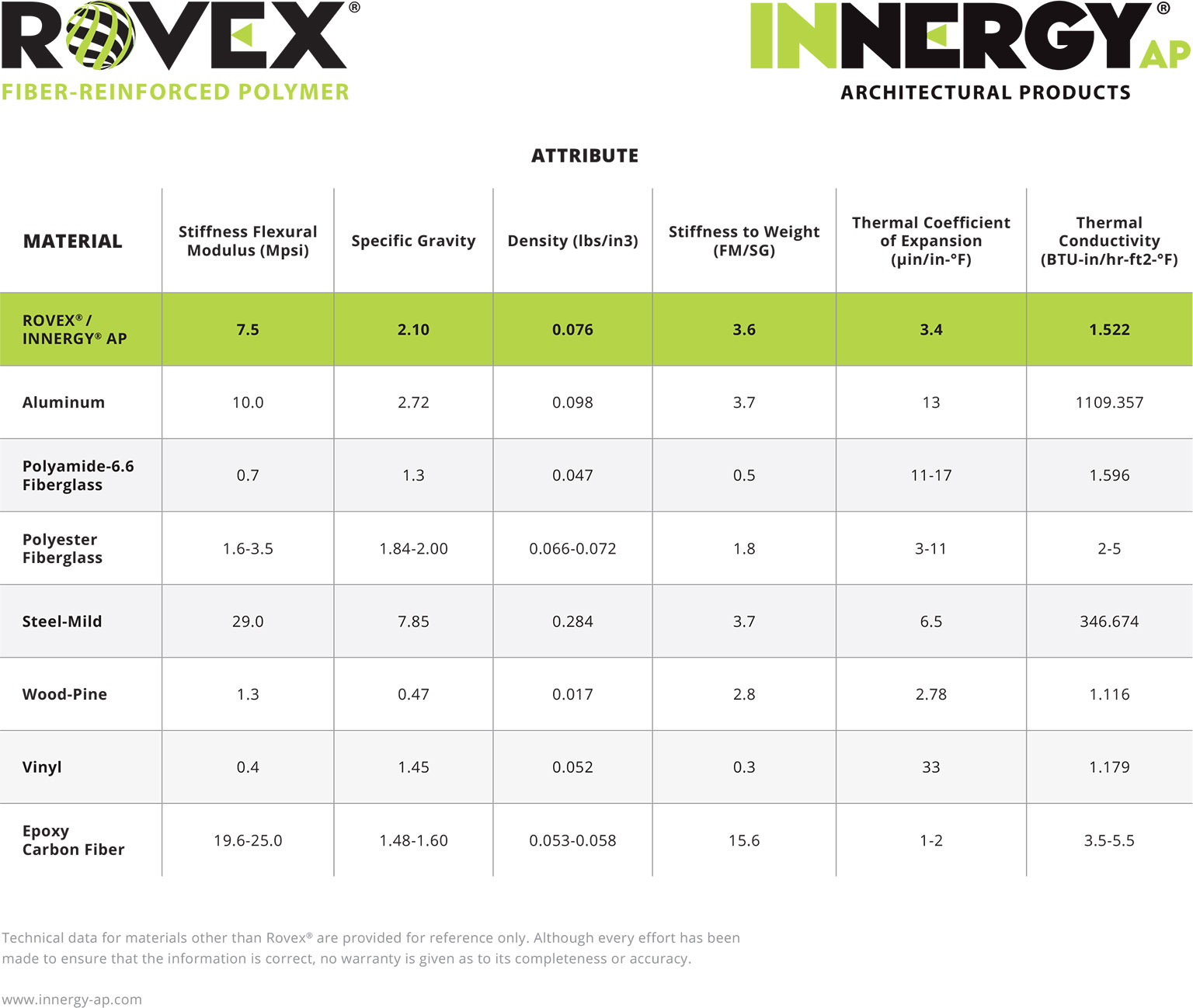

Very Low Thermal Conductivity

ROVEX: 1.52 BTUs / sq. ft. / degree F

Polyamide: 1.596 BTUs

Fiberglass: 2-5 BTUs

Aluminum 1,350 BTUs

Rovex is 900 times more energy efficient than aluminum

Metal-Like Stiffness

ROVEX: 7,500K PSI flexural modulus

Polyamide: 700K

Fiberglass 1,600-3,500K

Aluminum: 10,000K

High Resistance to linear compression, screw pull-out, abrasion, cracking, splitting and flexural fatigue

Unaffected by environmental conditions like salt air/water corrosion, water absorption, extreme hot/cold climates and most common chemicals

Highly Compatible with Coatings and Adhesives

Excellent performance with many paints, adhesives and powder coating; Arkema-approved for high-quality outdoor color performance using Kynar® Aquatec® coating technology.

Fabrication Options

Wet saw to minimize dust

Diamond-plated saw blade

Waterjet for complex cutting & routing

On-Site or Factory Assembly

Aluminum joinery or corner key techniques

Mechanical fastening with corner gussets

Screw fasteners are very effective